Chemical Engineers rely on modern modeling and simulation tools to design and optimize reactors. Solar-fuel reactors are a type of emerging chemical reactors.

To produce solar fuels, each of the following processes are highly coupled: light absorption, charge separation, photocatalysis, as well as chemical transport and separation.

Particle reactors

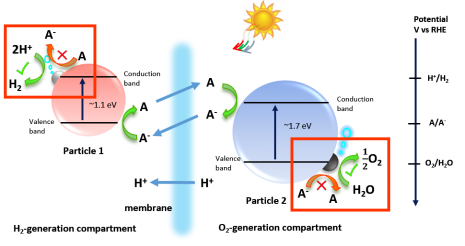

In a Type 2 reactor for visible-light driven water splitting, two types of particles, Particle 1 and Particle 2, with band gaps of ~ 1.1 and ~1.7 eV, are employed instead of only one particle. Each type of particles is drawn with its particle shape overlapped with its band energy diagram. Particle 1 performs photon-driven proton-reduction reaction through a hydrogen-evolving co-catalyst electrically connected to the conduction band (if applicable), while photo-generated hole charges oxidize A- to A. Particle 2 performs photon-driven water-oxidation reaction through an oxygen-evolving co-catalyst (if applicable), while photo-generated electron charges re-reduce A back to A-.

A/A- is a generic form of redox mediators, such as halides (IO3-/I- or I3-/I-), iron complexes (Fe3+/2+ or [Fe(CN)6]3-/4-) or Co complexes ([Co(bpy)3]3+/2+ or [Co(phen)3]3+/2+). The redox mediator A/A- shuttle change back and forth between the two reactor vessels.

Multi-physics optimization

One challenge involves large distances for redox mediators, A/A-, to transport in the solution as well as the membrane, pH gradients between the two compartments, and unknown dimensions for the reactor construct, etc.

Significant modeling and simulation work as well as experimental validation are needed to optimize these device designs.