Through a systematic effort of monitoring photo-corrosion with operando microscopy and spectroscopy, we first understand typical photoanode corrosion process with a detailed description for the different corrosion stages. Secondly, we use our photocorrosion model to explain how various protection or corrosion behavior is manifested in shifts of surface corrosion potentials. In doing so, we can categorize and report the main factors influencing anode stability during PEC water oxidation. Last but not the least, we can determine a set of operation conditions in which GaAs would be passivated for photo-corrosion but active for water splitting. Our preliminary results show GaAs could be stable in the electrolytes of pH = 3 to 9 during PEC water oxidation due to self-passivation as such acid PH condition is the typical PH value on GaAs surface even it is initially immersed in basic electrolyte. Accordingly, because the original GaAs/TiO2/Ni photoanode protective scheme has shown performance instability at neutral pH due to the dissolution of Ni cocatalyst, we propose this TiMnOx/Ir as new protective coating/cocatalyst scheme as an improved photoanode design to reach the DOE efficiency and stability targets.

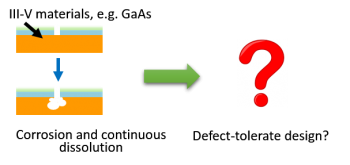

In principle, isolation of defective regions via discrete wires, instead of planar, should mitigate this failure mechanism. ALD TiO2 has been shown to stabilize discrete Si wire arrays for 2200 hours of continuous water oxidation. Question is: Can we design devices in a discrete geometry and achieve thousand-hour stability?

We use Polarization Modulation(PM)-FTIR to perform Infrared Reflection Absorption Spectroscopy (IRRAS) operando studies of metal electrodes during electrochemical methane oxidation. Direct conversion of methane gas to liquid fuels such as methanol is important for efficient natural gas utilization, however the stability of the methane molecule has hampered selective conversion. Using IRRAS we can detect when and under what conditions chemical processes such as adsorption, reaction, and desorption occur. We can also use this technique to identify surface intermediates, map reaction pathways, and quantify activation barriers and rate constants for various steps. By breaking down this complex reaction system into finite steps we can better understand how methane oxidation occurs on metal surfaces in order to enable the discovery of more active and selective methane oxidation catalysts.