Our strategy for durability is metal oxides based heterostructure interfaces in order to achieve efficient and stable photoelectrochemical water oxidation. We developed a new class of ternary oxide coating, (Ti,Mn)Ox, for efficient charge separation and stable water oxidation in acid.

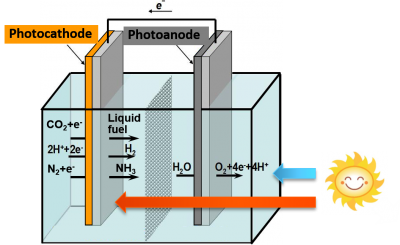

Photoelectrochemical water splitting captures solar energy and stores it into the bonds of produced solar fuel (usually O2 and H2). So it has long been considered as option to mitigate energy crisis and global climate change. However, there are still lots of challenges in designing an efficient and stable PEC cell to split water that lasts for more than hundreds of hours. Except for efficiency and cost, stability problem of efficient semiconductor/liquid interfaces using Si and GaAs materials has greatly hindered the development of many potential excellent photoanodes because of photo-corrosion during photoanodic operation.

Previously rejected from the microelectronic industry, electronically “leaky” ALD TiO2 coatings allow for facile hole-charge transport through other

wise blocking semiconductor/ TiO2 barriers, and therefore stabilize an entire class of efficient but otherwise unstable semiconductors for efficient water splitting.

Atomic-layer Deposition (ALD) coatings

A general strategy was shown to stabilize an entire class of efficient but otherwise unstable materials – including Si, GaAs, GaP, InGaP, CdTe, BiVO4 and structured Si wires – using an amorphous ALD TiO2 coating. This development brings exciting implications toward practical, large-scale, solar energy utilization.

On the right, it shows a 10% efficient and 100 hour stable prototype (courtesy E. Verlage). It splits water into 2:1 ratio of H2 and O2, with efficiency 10 times of nature’s photosynthesis. This has been successfully demonstrated.

It is achieved by a combination of an ALD protective coating strategy and efficient III-V tandems. Materials used for solar fuel applications are commonly subject to photo-corrosion and degradation, which diminish efficiency to zero over a few hours.

Thousand-hour stability?

It seems that once we have efficient tandems to power water splitting, we should be able to hit >10% targets with thousand-hour stability. In fact, those TiO2-protected III-V tandems start to develop corrosion pits inevitably at ~100 hours. Therefore, they fail well before thousand hours. Based on laboratory and field experience, corrosion protection will not be robust unless the underlying material is either immune to corrosion (like TiO2) or is operating in the passive regime (like Si in most pH) thus preventing active corrosion and dissolution.